BNSF RAILWAY ...im Modellbau - Rollmaterial - Steamlokomotives - Baldwin 4-8-4 Northern #3751 ATSF

Ist zu Reparatur zwecken seit März 2015 bei Ferdi Rat.

21.05.2016

Sie ist endlich nach langem wieder zurück von Ferdi Rat. Er musste sie komplett neu Programmieren.

equipment. That year also saw the last class 3 general overhaul for No. 3751 at Albuquerque; upon its release, it was assigned to the Los Angeles division. Working out of the Redondo Junction roundhouse, No. 3751 protected extra sections and special trains to Barstow, served as passenger helper out of San Bernardino, and handled the Del Mar Race Track trains and locals 75-70 between Los Angeles and San Diego. When a diesel was out of service, the 4-8-4 would handle the streamlined San Diegan trains, on time. Class 5-H repairs were made at Albuquerque in December 1951 and December 1952, and upon its return to Los Angeles, No. 3751 ran 3,954 miles in January and February 1953. March through June saw it stored serviceable, but the pioneer 4-8-4 was returned to service in July to assist in a heavy movement of special trains to and from the Boy Scouts' encampment at Santa Ana. After covering 5,319 additional miles, it was laid up at Redondo Junction on August 23, 1953. A 26-year career as a passenger locomotive was finished. Always dependable, No. 3751 didn't owe 'Uncle John' a dime when it completed its last mile in regular service.

equipment. That year also saw the last class 3 general overhaul for No. 3751 at Albuquerque; upon its release, it was assigned to the Los Angeles division. Working out of the Redondo Junction roundhouse, No. 3751 protected extra sections and special trains to Barstow, served as passenger helper out of San Bernardino, and handled the Del Mar Race Track trains and locals 75-70 between Los Angeles and San Diego. When a diesel was out of service, the 4-8-4 would handle the streamlined San Diegan trains, on time. Class 5-H repairs were made at Albuquerque in December 1951 and December 1952, and upon its return to Los Angeles, No. 3751 ran 3,954 miles in January and February 1953. March through June saw it stored serviceable, but the pioneer 4-8-4 was returned to service in July to assist in a heavy movement of special trains to and from the Boy Scouts' encampment at Santa Ana. After covering 5,319 additional miles, it was laid up at Redondo Junction on August 23, 1953. A 26-year career as a passenger locomotive was finished. Always dependable, No. 3751 didn't owe 'Uncle John' a dime when it completed its last mile in regular service.

As a result of studies made on the Santa Fe during the past few years with a view to determining the wheel loading, distribution of weights and method of counterbalancing which will keep track stress within safe limits, a loading of trucks and driving axles of locomotive No. 3751 was adopted. For purposes of comparison, the wheel loads of locomotive No. 3710, a previous Santa Fe Mountain type locomotive, are also compared. All of the driving wheels on locomotive No. 3751 have flanged tires, and no driving box lateral motion device is provided. The tires on No.1 and No. 4 wheels are set 1/8 in. nearer together than on the main and No. 3 wheels. Three-eighths inch lateral motion is provided on the front truck wheels, 3/16 in. on all drivers and on the forward trailer truck wheels, and 3/8 in. on the back wheels of the trailer truck. In general, the maximum static loads were kept to 70,000 lb. per axle and the combined static and dynamic loads to 76,000 lb. per axle. The effectiveness of this design, together with accurate cross counterbalancing and a division of the trailer-truck load between two axles, has been such as to permit increasing driving-axle loads almost 10,000 lb. in locomotive No. 3751 as compared with locomotive No. 3710 and at the same time to develop lower peak track stresses.

All of the driving wheels on locomotive No. 3751 have flanged tires, and no driving box lateral motion device is provided. The tires on No.1 and No. 4 wheels are set 1/8 in. nearer together than on the main and No. 3 wheels. Three-eighths inch lateral motion is provided on the front truck wheels, 3/16 in. on all drivers and on the forward trailer truck wheels, and 3/8 in. on the back wheels of the trailer truck. In general, the maximum static loads were kept to 70,000 lb. per axle and the combined static and dynamic loads to 76,000 lb. per axle. The effectiveness of this design, together with accurate cross counterbalancing and a division of the trailer-truck load between two axles, has been such as to permit increasing driving-axle loads almost 10,000 lb. in locomotive No. 3751 as compared with locomotive No. 3710 and at the same time to develop lower peak track stresses.

The comparative effects of these two locomotives on tangent track at 60 miles per hour are plainly shown in Chart I which gives the equivalent static load on each pair of drivers through a complete revolution. A glance at the chart shows that in locomotive No. 3751, the No. 1 driving wheels have been made to take more nearly a fair share of the equivalent static load than was the case with locomotive No. 3710, and as a result, the main and particularly the No. 3 wheels have been relieved of excessive loading. The chart shows that locomotive No. 3751 at 60 miles per hour on tangent track provides about 3,000 lb. less maximum equivalent static load on the rails than locomotive 3710, in spite of having from 9 to 15 per cent greater individual driving axle loads.

The stresses in both rails occasioned by locomotive 3751 passing a 10-deg. curve at three different speeds are examined. In general, the comparison indicates that the loads are fairly well distributed between the driving wheels and trucks under all curve and speed conditions; at least excessive peak loads from any one pair of wheels are avoided. Similar comparisons to those reproduced here for locomotive No. 3751 were developed for locomotive No. 3710 and published in the 1926 proceedings of the American Railway Association, Mechanical Division. In fact, the results of the tests reported at that time served as the basis for the distribution of the wheel loads in the present locomotive.

To illustrate how peak rail loads have been avoided by the design of locomotive N. 3751, a reference to the diagram for locomotive N. 3710, published in 1926, shows that at five miles an hour the No. 3 driving wheels cause a stress of about 46,000 lb. per sq. in. on the outside edge of the base of the inner rail on a 10-degree curve. With locomotive No. 3751, this stress at the slightly greater speed of 10 miles an hour has been reduced to 32,000 lb. per sq. in., as indicated in Chart II. At 25 miles an hour on the same curve, the No. 3 wheels of locomotive No. 3710 cause a maximum rail stress of about 35,000 lb. per sq. in., whereas the No. 3 wheels on locomotive N. 3751 cause a stress of only 32,000 lb. per sq. in. The records show that the trailer wheels of locomotive No. 3710, in passing a 10-deg. curve at 25 or more miles an hour, introduce a stress in excess of 40,000 lb. per sq. in. in the outside edge of the base of the outer rail. The trailer truck design on locomotive No. 3751, with the division of the load between two axles and a substantially shorter distance between the No. 4 driving and No. 1 trailer wheels, overcomes this difficulty.

The locomotive tender is constructed with a Commonwealth one-piece cast steel underframe having end sills cast integral and designed to accommodate the Franklin unit drawbar arrangement. Six-wheel trucks are applied, with cast steel side frames having riveted liners on the pedestal wear faces. Tatum-Zell type journal boxes are used. The tender has a capacity for 15,000 gal. of water and 20 tons of coal. The general dimensions of the new locomotive, as compared with a previous mountain type locomotive.

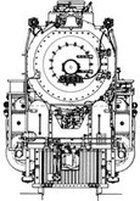

The cylinders of the 3751-class locomotive are combined in a one-piece steel casting representing a saving in weight of approximately 25 per cent over cylinders of cast iron. This steel cylinder casting is bolted and keyed to a locomotive bed and cradle frame cast of steel in one piece, with separate steel front deck casting in order to facilitate repairs in case of accidental collision. The steam and exhaust passages of the cylinders are designed free from restrictions and obstructions to the flow of steam. The exhaust passages are gradually reduced in area from the valve bushings to the base of the exhaust pipe in such a way that the cross section at no point is larger than a preceding section. All fillets have at least ' in. radius.

The front engine truck is of the constant-resistance type with Commonwealth cast-steel frame, 33-in. solid rolled steel wheels, and 6-in. by 11-in. journals. The trailer truck is of the four-wheel Delta type with constant-resistance rockers and has a one-piece cast-steel frame. Both pairs of trailer wheels are 40 in. in diameter, the journals being 9 in by 14 in. Brass pedestal wearing liners are riveted to the truck frame.

The driving wheels are 73 in. in diameter, and in order to apply a boiler of the desired diameter and capacity, it was found necessary to use driving springs with reverse camber. The driving wheel centers are 66 in. in diameter and mounted on hollow-bored axles, the main axle being 13 in. in diameter and the others 12 in. The main crank pin is also hollow-bored with a four inch hole to reduce weight and provide for delivery of grease under pressure to the center of the main and side rod floating bushings. Flange tires are provided on all driving wheels, spaced as follows: Front wheels, 53 1/8 in.; main wheels, 53' in.; No. 3 wheels, 53' in.; No. 4 wheels, 53 1/8 in. Revolving weights and 50 per cent of the reciprocating weights are counterbalanced, revolving weights in the main wheels being cross-counterbalanced.

The static and dynamic load on these wheels is kept under 76,000 lb. per pair of wheels. The driving boxes have a bearing 13 in. long on the journals and are equipped with phosphor-bronze brasses with babbitt inserts and Elvin grease cellars. The shoes and wedges are also made of phosphor bronze. The normalized carbon-steel main rods have floating bushings on the back ends and front ends tapered to prevent galling in the reinforced Laird type crossheads. Grease cups are forged solid with the rod and off center to give a stronger construction. Pistons are of the Universal three-bull-ring type. Walschaert valve gears are supplied with an additional lever interposed between the radius rod and combination lever and pivoted at the rear end of the back valve cylinder head. This arrangement, covered by a patent application, magnifies the motion produced by the link but does not affect the motion produced by the combination lever and affords a longer valve travel than usual with Walschaert gear without exceeding the normal limits of angularity. The maximum travel obtained is nine inches, and in order to take full advantage of this travel and permit finer adjustments of cutoff, the Ragonnet power reverse gear is operated from the cab by a reverse lever and quadrant cut with more than the usual number of teeth.

The boiler of the new locomotive is designed for a minimum safety factor of four with a boiler pressure of 225 lb. It is of the wagon-top type, with conical barrel, the rear course of which is 99-15/16 in., and the first course 88 in. in outside diameter. The firebox has a grate area of 108 sq. ft. and is equipped with two 3' in. arch tubes, and two Nicholson thermic siphons. The combustion chamber is equipped with one thermic siphon. There are 221 superheater flues, 3' in. in diameter by 21 ft. long; and 59 tubes, 2' in. in diameter and of the same length. All of the superheater flues are electric welded to the back flue sheet and beaded in the front.

Price (In May of 1927): | $99,712.77 (Santa Fe paid $252,335 for 2926 in 1944) | |

Price (in 2012 dollars): | $1,303,662.16 | |

Type: | 4-8-4 3751 Class, 14 engines built 3751-3764. | |

Builder: | Baldwin Locomotive Works, Philadelphia, PA. | |

Service: | Passenger and Freight (Dual Purpose). | |

Driving Wheels: | 73" from 1927 to 1941, 80" from 1941 to present. | |

Boiler Diameter: | 88" | |

Grate Area: | 108 sq/ft. | |

Cylinders: | 30" x 30" With Wagner Bypass Valve | |

Current Steam Pressure: | 230 lbs. (originally 210 lbs.) | |

Wheel Base - Total: | Total 94' 10.5" | |

Wheel Base - Engine: | 46' 9" | |

Wheel Base - Driving: | 21' 3" | |

Wheel Base - Rigid: | 13' 10" | |

Weight: | Engine 478,100 lbs., Tender 396,246 lbs., Total 874,346 lbs. | |

Weight On Lead Truck: | 89,200 lbs. | |

Weight On Drivers: | 278,000 lbs. | |

Weight On Trailing Truck: | 100,000 lbs. | |

Driver Axle Loading: | 72,000 lbs. | |

Minimum Rail Size: | 90 lbs per yard | |

Minimum Switch Size: | #8 | |

Length: | Engine and Tender 108' 7" | |

Height: | 16' | |

Width: | 11' | |

Heating Surface: | 5,634 sq/ft. | |

Tractive Force: | 66,000 lbs. as built, 71,719 lbs. currently. | |

Horsepower: | Boiler - 5,000 hp, Cylinders - 3,900 hp, Drawbar - 3,600 hp. | |

Fuel/Capacity: | Coal 1927-36 (20 tons). Oil 7,101 gallons 1938-present. | |

Water Capacity: | 15,000 gallons 1927-1938, 20,000 gallons 1938-present. | |

Pulling Power: | 26 passenger cars, 1820 tons, level grade 65 m.p.h. or 15 passenger cars, 1050 tons, 2% grade, 20 m.p.h. or 105 freight cars, 5,949 tons, level grade, 45 m.p.h. | |

Speed Ratings: | 70 m.p.h. for 1927-1938. 90 m.p.h. for 1941-1953. | |

Length of Runs: | LA to La Junta, CO 1,235 miles. LA to Kansas City, KS 1,789 miles. LA to Wellington, KS 1,535 miles. | |

Quelle: http://sbrhs.org/specs.html und http://sbrhs.org/portfolio-items/specifications/ (19.01.2017) | ||

1926 | Santa Fe Railway, in cooperation with Baldwin Locomotive Works, designs Santa Fe's first 4-8-4, as a coal burner. | ||

1927 | In May, 3751 emerges from the erecting hall as the Santa Fe's and Baldwin's first 4-8-4, builder's number 60004. | ||

1928 | Tests show 3751 to be 20% more efficient and powerful than Santa Fe class 3700 4-8-2's. | ||

1936 | 3751 is converted to burn oil at the San Bernardino Shops. | ||

1938 | 3751 hauls the first named passenger train 'The Scout' into the new Los Angeles Union Passenger Terminal on opening day, May 7. | ||

1941 | 3751 completes it's modernization for high speed operation with a new frame, 80 inch drivers, and roller bearings all around, along with other upgrades. It's highest recorded speed was 103 miles per hour. | ||

1953 | 3751 pulls the last steam powered passenger train from San Diego on August 23, the engine's last revenue run before being stored serviceable temporarily at Los Angeles' Redondo Junction Roundhouse. | ||

1957 | Officially retired from the Santa Fe Locomotive roster and donated to the city of San Bernardino. | ||

1958 | 3751 is placed in Viaduct Park, San Bernardino as a static display May 14, 1958. 3751 becomes the oldest existing 4-8-4 as the first 12 built by Alco are scrapped by the Northern Pacific - as that railroad fully dieselizes. | ||

1981 | 3751 is placed in Viaduct Park, San Bernardino as a static display May 14, 1958. 3751 becomes the oldest existing 4-8-4 as the first 12 built by Alco are scrapped by the Northern Pacific - as that railroad fully dieselizes. | ||

1985 | 3751 is sold to the SBRHS by the city of San Bernardino for $1, with conditions - the SBRHS must restore and operate the locomotive. | ||

1986 | With the help of volunteers, the Santa Fe and a lot of panel track 3751 is moved out of Viaduct Park on April 30, and into California Steel Industries in Fontana, where the majority of restoration is performed (Please see Restoration Gallery). | ||

1991 | 3751 returns to steam on August 15. December 20 is the official Christening and Dedication Ceremony for the 3751 as she is returned to steam, the newly restored locomotive pulls a freight train from San Bernardino to Los Angeles as a break in run. The California Limited Excursion operates December 27-30 from Los Angeles to Bakersfield and return via Cajon and Tehachapi passes (Please see California Limited Gallery). | ||

1992 | 3751 pulls the Santa Fe Railway Employee Appreciation Special, August 30 to September 16, Los Angeles - Chicago - Los Angeles (Please see E.A.S to Chicago Gallery). | ||

1995 | On April 21 the 3751 is the last locomotive serviced at the Santa Fe's San Bernardino Yards Complex. Most of the 72 buildings in the yard complex will be demolished to make way for an intermodal facility. 3751 had been stored in the Car Shops of the complex, then the Santa Fe offered the SBRHS a siding between Lytle Creek wash and the Metrolink flyover just west of the Depot in San Bernardino - as a temporary home. April 22-23 3751 is displayed under steam at Riversides 'Sunkist Orange Blossom Festival'. | ||

1996 | 3751 is again displayed under steam at Riversides 'Sunkist Orange Blossom Festival', in April. | ||

1999 | The siding that the Santa Fe provided as a temporary storage site needed to be vacated, the SBRHS negotiates a lease with Amtrak to store the locomotive and tool car in the Redondo Junction Roundhouse in Los Angeles. To physically get there 3751 pulls a BNSF train to Hobart Yard in Los Angeles on January 12, and is stored at Amtrak's Redondo Junction Roundhouse (Please see Move to Redondo Gallery). SBRHS signs a lease for museum property (east of Santa Fe Depot) in San Bernardino on April 21, but the lease is never signed by the San Bernardino mayors office. Displayed under steam for Amtrak employee picnic on May 1 at Redondo Junction. Attend CSRM's 'Railfair 99' June 18-27 (Please see Railfair 99 Gallery). | ||

2000 | 3751 becomes the last steam locomotive to be serviced at the Redondo Junction Roundhouse before it was dismantled by Amtrak in August (sound familiar?). 3751 is again stored outside in the elements, however Amtrak provides a huge tarp to cover the locomotive with during the winter. Yes, it does rain in southern California. On October 4, 2000, steam locomotive No. 3751 was listed on the 'National Register of Historic Places' (NR Reference Number 00001178). | ||

2001 | In May the locomotive participates in a local event in Fullerton, CA and is displayed hot for the weekend at 'Fullerton Railroad Days'. SBRHS begins the FRA recertification process for 3751. | ||

2002 | 3751 completes its rebuilding for a new 15 year FRA boiler recertification. 3751 pulls a flawless trip to the NRHS Convention in Williams, Arizona - August 19-25. 3751 is also 75 years young this year, and still running strong (Please see Canyon Rails 2002 Gallery). | ||

2003 | Volunteers are busy early this year and raise a new compound fence, reorganize the Reefer Car, and work to replace cylinder rings and valves with funds raised through the 'Presidents Challenge'. SBRHS reviews operational opportunities and new locations for a home - not in San Bernardino. SBRHS volunteers work to complete the cylinder work and prepare the engine for its scheduled trip to San Diego in September, which was cancelled as no insurance could be found, an attempt to reschedule is planned for the spring of 2005. Volunteers participate in fundraising events at Fullerton Railroad Days on May 5 and the San Bernardino Orange Show on May 24-26. | ||

2004 | 3751 is invited to participate in the re-opening of the San Bernardino depot after its extensive restoration process. SBRHS hosts their first Educational Outreach Program in San Pedro, California. | ||

2005 | 3751 appears at a private steam up at Los Angeles Union Station for Metrolink as they host the American Public Transportation Association (APTA) Annual Commuter Rail Conference on April 2-3. 3751 participates in a private steam up on April 30th for the Los Angeles Railroad Historical Foundation (LARHF) when they tour the locomotive at Redondo Junction during a Santa Fe retrospective in Los Angeles. The 3751 attends Fullerton Railroad Days on May 7-8. On June 23, the 3751 is steamed up and on display at Los Angeles Union Station for the Santa Fe Railway Historical & Modeling Society Convention. | ||

2006 | 3751 is rolled out for another edition of the Educational Outreach Program at Los Angeles Union Station of February 6-9 to the delight of 850 school children. Schools from Wilmington, Burbank, Los Angeles and San Pedro attended this event. | ||

2007 | SBRHS hosts two more hugely sucsessful Educational Outreach Programs, the first is held February 11-17 at Los Angeles Union Station and the second being held in San Pedro April 15 to 22. Between these two events 3751 was visited by 1,550 school children during the SBRHS's Educational Outreach Program this year. | ||

2008 | In May, 3751 participates in the last ever Fullerton Railroad Days On June 1, 3751 makes an historic return to San Diego for the first time in 55 years pulling an excursion train for the Central Coast Chapter of the National Railway Historical Society. In September, 3751 returns to San Diego for second time pulling the annual Amercian Association of Private Rail Car Owners (AAPRCO) excursion train. | ||

2009 | In May, 3751 is fired up for participation in the Amtrak Employee Appreciation Day at the Amtrak 8th Street Yard. 3751 and crew play host to Amtrak President Joseph Boardman, who tours the locomotive cab. 3751 participates in National Train Day and is put on display at Los Angeles Union Station. | ||

2010 | The weekend of May 1st and 2nd, 3751 takes an overnight train to San Diego and return. This is the third trip to San Diego in 2 years for 3751. The day before the trip, 3751 and crew again participate in Amtrak's Employee Appreciation Day at the 8th Street Yard in Los Angeles. 3751 travels to San Bernardino for National Train Day and the City of San Bernardino Bi-Centennial celebration. | ||

2011 | The weekend of April 16th and 17th, 3751 again travels to San Bernardino with a passenger train for the City's annual Railroad Days at the historic Santa Fe Depot. 3751 participates in National Train Day at Los Angeles Union Station. 3751 is steamed up and put on display at Los Angeles Union Station December 10 and 11 in conjunction with Amtrak's 40th Anniversary Museum Train. 3751's attendance helps make this event one of the most attended in the museum train's year long cross-country journey. | ||

2012 | The weekend of April 21st and 22nd, 3751 again travels to San Bernardino with a passenger train for the City's annual Railroad Days at the historic Santa Fe Depot. 3751 again participates in National Train Day at Los Angeles Union Station on May 12th. On Monday, May 14th, 3751 departs Los Angeles for a return to the Grand Canyon. Over six days the "Grand Canyon Limited II" travels over 1,300 miles as part of the Arizona Centennial Celebration. The successful trip is sponsored by the Central Coast Railway Club. 3751 is also 85 years young this year, and still running strong. | ||

2013 | 3751 is 85 years young this year and still running strong. 3751 steams to San Bernardino with a passenger train for the City's annual Railroad Days event at the historic Santa Fe Depot over April 20-21, sporting former Super Chief dormitory/lounge car Acoma, among other historic passenger cars. 3751 is also displayed under steam for National Train Day on May 12 at Los Angeles Union Station. During this event, the SBRHS auctions an original painting of 3751, which was painted by local artist & career railroader, Eric Smith, whom donated this work to the SBRHS to be used as a fundraiser and basis of future merchandise. In late 2013, 3751 is brought out to Los Angeles Union Station as a backdrop for the filming of an episode of “Mob City." 3751’s whistle is recorded for use by Metrolink. | ||

2014 | For the 5th consecutive year, 3751 proudly steams from Los Angeles to San Bernardino and return with a five car passenger cars on April 12 - 13. The five cars included: a Metrolink Bombardier Bi-level coach wrapped in the company's "STAY ALERT - STAY ALIVE" red safety wrap, Amtrak's sole full-length dome car, the Ocean View, an Amtrak Amfleet coach, the ex-Santa Fe Super Chief lounge car, Acoma and the ex-Canadia National business car, Tioga Pass. This trip, apart of the city's annual San Bernardino Railroad Day's celebration, would mark the last trip 3751 could make to San Bernardino for at least two years as Metrolink began development of new track alignments at the jointly used Amtrak - Metrolink depot. | ||

2015 | With the full support of the Southern California Railway Plaza Association (SCRPA), the BNSF Railway and Amtrak - 3751 proudly returns to Fullerton Railroad Days after a seven year hiatus from the popular event. On the evening of April 30, the locomotive is towed backwards by the BNSF display unit also attending the event from Amtrak's 8th Street yard to Fullerton, arriving at its display location just after midnight. Following an entire day of preparations now at Fullerton, 3751 is warmly greeted by over 35,000 people during the two day event spanning May 2 - 3 before returning to Los Angeles on the evening of the 3rd. Also taking place at the beginning of 2015, the restoration of the future support car 1517 begins. The society's reefer box-car departs the SBRHS Redondo facility in late October and is moved to Anaheim. | ||

2016 | 3751's first steam up of 2016 finds it attending the California Passenger Rail Summit at Los Angeles Union Station on April 13th and 14th. A few short weeks later, the locomotive was again under steam and takes part in the annual Fullerton Railroad Days event on April 30th through May 1st. During the engine's display in Fullerton, the SBRHS conducts the society's first ever, closed night photography session. On the engine's return to Los Angeles, the SBRHS conducts a photo session of the display consist at the depot as it is the first BNSF - mainline steam movement to operate under the control of Positive Train Control (PTC). On July 28th, 3751 participates in Metrolink's unveiling ceremony for the new Tier 4, F125 unit at Los Angeles Union Station. Roughly a month later on the evening of September 27th, 3751 leads two leased BNSF units from Los Angeles Union Station to the Acton-Vincent Grade Station to participate the following day in Metrolink's dedication ceremony of a second platform here. 3751's 120-mile trip to Acton and return marked the first time a steam locomotive had traveled north of Los Angeles in 24 years and the first time in 32 years a steam locomotive traveled through Soledad Canyon. | ||

2017 | In early May, 3751 again steams to the annual Fullerton Railroad Days event. On the second evening of its stay, the SBRHS holds its second close night photography session that includes many reenactors and an original, WWII 1944-built Jeep. In mid-July, 3751 makes an appearance at the Summer Trainfest at Los Angeles Union Station. At the conclusion of this event, the SBRHS hosts the first formal, night photography session on the grounds of the Redondo turntable with 3751 posed in different angles on the table with reenacts and vintage vehicles. For its last outing of 2017, 3751 joins the second annual L.A. Union Station Holiday TrainFest & Toy Drive. | ||

| 2018 | Seit/since 03/2024 TIMELINE PAGE UNDER CONSTRUCTION - COME BACK SOON! -SBRHS WEBSITE TEAM | |

| 2019 | Next Text... | |

| 2020 | Next Text... | |

| 2021 | Next Text... | |

| 2022 | Next Text... | |

| 2023 | Next Text... | |

| 2024 | Next Text... |

Road / Engine No. | Current Status | Year Built / Builder | Cl. | Drivers in Inches | Engine Weight | Engine & Tender Weight | Tractive Effort | Cylinders | Boiler Pressure | Length |

QJ 7081* | Pulled last regularly scheduled mainline steam train in China. Currently used for special operations on the Iowa Interstate Railroad Limited. | Late 1980's | QJ | 1500mm (59 inches) | n/a | 220 Tons with 8 wheel tender / 253 Tons with 12 wheel tender | 282kn | 650mm diameter (25.59 inches) x 800mm stroke (31.49 inches) | 14.7 bar (213 lbs) | 26.0 meters for 8 wheeled tender (85.3 ft) / 29.2 meters for 12 wheeled tenders (95.8 ft) |

GTW 6325 | Stored near Sugercreek, Ohio waiting to be moved into the Age of Steam Roundhouse following completion of its construction. | 1942-43 / Alco | U-3-B | 73 inches | 403,000 lbs (Lightest) | 673,500 lbs | 59,000 lbs (Least) | 26 inches x 30 inches (Smallest) | 250 lbs | 96 feet (Shortest) |

Cotton Belt 819 | Stored at Arkansas Railroad Museum, needs FRA recertification | 1943 / Cotton Belt | L-1 | 70 inches (Smallest) | 419,800 lbs | 737,500 lbs | 61,564 lbs | 26 inches x 30 inches (Smallest) | 250 lbs | 99 feet 8.5 inches |

Reading 2100 | Stored serviceable on a siding in Richland, Washington (Reading Railroad Online). | 1947 / Reading | T-1 | 70 inches (Smallest) | 447,300 lbs | 844,000 lbs | 68,000 lbs (79,100 lbs with booster) | 27 inches x 32 inches | 240 lbs | 110 feet 6 inches |

Milwaukee Road 261 | Undergoing FRA recertification at Minneapolis Junction by Friends of the 261 | 1943 / Also | S-3 | 74 inches | 460,000 lbs | 824,100 lbs | 62,040 lbs | 26 inches x 32 inches | 250 lbs | 109 feet 8 inches (with coupler extended) |

SP 4449 | Operational. Based out of Portland, Oregon. Maintained by the Friends of SP4449 | 1941 / Lima | GS-4 | 80 inches (Largest) | 475,000 lbs | 865,750 lbs | 64,800 lbs (unknown with booster assistance) | 25.5 inches x 32 inches | 300 lbs (Highest) | 101 feet 5 inches |

ATSF 3751 | Operational. Based out of Amtrak's Los Angeles Locomotive Facility. Full list of current specs here. Angeles Locomotive Facility. Full list of current specs here. | 1927 / Baldwin (Oldest) | 3751 | 80 inches (Largest) | 478,100 lbs | 874,346 lbs | 66,000 lbs (as built) 71,719lbs** (after 1941 rebuild) | 30 inches x 30 inches | 230 lbs (Lowest) | 108 feet 7 inches |

C&O 614 | Remains for sale. Stored at Reading & Northern Engine Facility in Port Clinton, PA. (Chesapeake & Ohio 614) | 1948 / Lima | J-3A | 72 inches | 482,200 lbs | 865,530 lbs | 68,300 lbs (80,700 lbs*** with booster) | 27.5 inches x 30 inches | 255 lbs | 112 feet |

SP&S 70 | Operational. Based out of Portland, Oregon. Maintained by the Pacific Railroad Preservation Association | 1938 / Baldwin | E-1 | 77 inches | 485,500 lbs | 871,550 lbs | 69,500 lbs | 26 inches x 31 inches | 260 lbs | 110 feet 7 inches |

UP 844 | Operational. Owned by Union Pacific Railroad and based out of Cheyenne, Wyoming. Maintained by the Union Pacific Steam Program | 1944 / Alco | FEF-3 | 80 inches (Largest) | 486,340 lbs | 907,890 lbs | 63,800 lbs | 25 inches x 32 inches | 300 lbs (Highest) | 114 feet 3 inches |

N&W 611 | Stored at the Virginia Museum Of Transportation in Roanoke, VA. for display only | 1950 / N&W Roanoke (Youngest) | J | 70 inches (Smallest) | 494,000 lbs | 873,000 lbs | 80,000 lbs | 27 inches x 32 inches | 300 lbs (Highest) | 109 feet 2 inches |

ATSF 2926 | Undergoing restoration to operation in Albuquerque, New Mexico by NMSL&RHS | 1944 / Baldwin | 2900 | 80 inches (Largest) | 510,150 lbs (Heaviest) | 961,000 lbs (Heaviest) | 86,922 lbs** (Strongest) | 28 inches x 32 inches (Largest) | 300 lbs (Highest) | 120 feet 10 inches (Longest) |